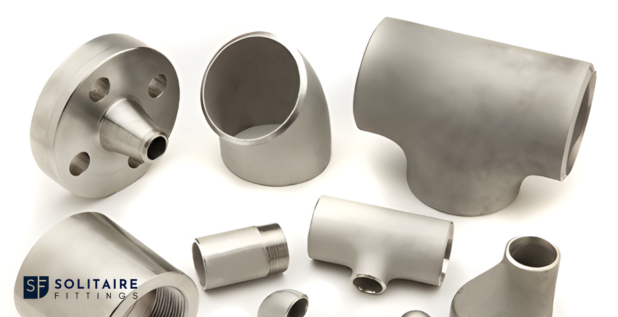

At Solitaire Fittings, we specialize in manufacturing and supplying Stainless Steel ASTM A403 WPS31254 Buttweld Fittings that deliver exceptional strength, superior corrosion resistance, and long-lasting performance. Designed for critical industrial applications, these fittings are made from high-alloy austenitic stainless steel (UNS S31254), often referred to as 6Mo stainless steel, known for its high molybdenum content and remarkable resistance to pitting and crevice corrosion.

Whether you require WPS 31254 Elbows, Tees, Reducers, Stub Ends, or Caps, we ensure precision engineering, compliance with ANSI B16.9 standards, and guaranteed durability. As a trusted Supplier and Exporter of ASTM A815 WPS31254 Duplex Stainless Steel Pipe Fittings in India, Solitaire Fittings provides tailor-made solutions to meet global standards.

What Are Stainless Steel ASTM A403 WPS31254 Buttweld Fittings?

Stainless Steel WPS31254 Buttweld Pipe Fittings are components used to connect, redirect, or terminate pipelines in industries handling aggressive chemicals, seawater, or high-temperature fluids. These fittings are welded directly to the pipe, ensuring leak-proof joints and long service life.

The ASTM A403 WPS31254 grade is a super-austenitic stainless steel with:

- High molybdenum content (6%) for superior resistance to pitting.

- Excellent chloride resistance, making it suitable for seawater and brackish environments.

- High tensile and yield strength ensuring reliable performance under pressure.

- Low carbon content, reducing the risk of intergranular corrosion after welding.

This makes WPS31254 Stainless Steel Buttweld Pipe Fittings a preferred choice for industries such as:

- Marine & Offshore Engineering

- Chemical Processing

- Oil & Gas Refineries

- Pulp & Paper Industry

- Power Generation Plants

Key Features of ASTM A403 WPS31254 Buttweld Fittings

- Superior Corrosion Resistance – Performs exceptionally well in seawater, acidic, and chloride-rich environments.

- High Strength – Maintains structural integrity even under extreme pressure and temperature conditions.

- Weldability – Designed for easy welding without risk of carbide precipitation.

- Durability – Long service life with minimal maintenance.

- Compliance – Manufactured in accordance with ANSI B16.9, ASTM A403, and ASTM A815 standards.

Types of Stainless Steel WPS31254 Buttweld Pipe Fittings

At Solitaire Fittings, we manufacture and supply all standard configurations of ASTM A815 WPS31254 Duplex Stainless Steel Pipe Fittings, including:

➤ WPS 31254 Elbow

- Available in 45°, 90°, and 180° bends.

- Redirects pipeline flow efficiently.

- Manufactured to ANSI B16.9 SS WPS31254 Buttweld Fitting standards.

➤ Reducers (Concentric & Eccentric)

- Used to connect pipes of different diameters.

- Ensures smooth fluid transition with minimal pressure loss.

➤ Tees (Equal & Unequal)

- Distributes flow into branch pipelines.

- Available in equal and reducing designs.

➤ SS WPS31254 Stubends

- Commonly used with lap joint flanges.

- We are a leading SS WPS31254 Stubends Dealer in India and abroad.

➤ Caps & Crosses

- Pipe caps are used to seal pipe ends.

- Cross fittings connect four pipelines at right angles.

Applications of WPS31254 Stainless Steel Buttweld Fittings

- Marine Engineering – Piping systems exposed to seawater.

- Chemical Plants – Handling of sulfuric acid, phosphoric acid, and chlorides.

- Desalination Plants – Resistance against chloride-induced corrosion.

- Paper & Pulp Industry – High resistance to bleaching chemicals.

- Oil & Gas Refineries –

Mechanical Properties of ASTM A403 WPS31254 Stainless Steel Pipe Fittings

| Property | Value |

|---|---|

| Tensile Strength | 650 MPa (min) |

| Yield Strength (0.2% offset) | 300 MPa (min) |

| Elongation | 35% (min) |

| Hardness | 95 HRB max |

Chemical Composition – Stainless Steel WPS31254 Buttweld Fittings

| Element | Content % |

|---|---|

| Carbon (C) | 0.020 max |

| Manganese (Mn) | 1.0 max |

| Phosphorus (P) | 0.030 max |

| Sulfur (S) | 0.010 max |

| Silicon (Si) | 0.80 max |

| Chromium (Cr) | 19.5 – 20.5 |

| Nickel (Ni) | 17.5 – 18.5 |

| Molybdenum (Mo) | 6.0 – 6.5 |

| Nitrogen (N) | 0.18 – 0.22 |

Physical Properties of Stainless Steel ASTM A403 WPS31254

| Property | Value |

|---|---|

| Density | 8.0 |

| Melting Point | 1350 – 1390 |

| Thermal Conductivity (at 20°C) | 14.0 |

| Specific Heat Capacity | 500 |

| Electrical Resistivity (at 20°C) | 0.98 |

| Magnetic Permeability | 1.0 (Non-Magnetic) |

Specifications Chart – SS SMO 254 (UNS S31254)

| Specifications | Standard |

|---|---|

| Material Grade | SMO 254 (UNS S31254) |

| Standard | ASTM A403 / ASME SA403 |

| Dimensions | ASME/ANSI B16.9, B16.28, MSS-SP-43 |

| Sizes | ½” to 48” (DN15 – DN1200) |

| Type | Seamless / Welded / Fabricated |

| Schedule | SCH 10S, SCH 40, SCH 80, SCH 160, XXS & Custom |

| End | Beveled / Plain / Butt Weld Ends |

Why Choose Solitaire Fittings for ASTM A815 WPS31254 Buttweld Pipe Fittings?

As one of the leading Suppliers and Exporters of ASTM A815 WPS31254 Duplex Stainless Steel Pipe Fittings in India, Solitaire Fittings offers:

- Global Export Network – Supplying across USA, Europe, Middle East, and Asia.

- Custom Manufacturing – Fittings available in special sizes and shapes as per client requirements.

- Quality Assurance – Products tested under strict quality parameters including PMI, IGC, and hydro testing.

- Competitive Pricing – Best value for premium-quality stainless steel fittings.

- Ready Stock Availability – Quick delivery for urgent industrial needs.

Leading ASTM A403 WPS31254 Buttweld Fittings Suppliers in India

Stainless Steel ASTM A403 WPS31254 Buttweld Fittings are a reliable solution for industries that demand high strength, superior corrosion resistance, and long service life. At Solitaire Fittings, we ensure every product meets international standards and delivers outstanding performance in the toughest environments.

If you are looking for a trusted supplier and exporter of ASTM A815 WPS31254 Duplex Stainless Steel Pipe Fittings in India, Solitaire Fittings is your go-to partner.

Request Your Stainless Steel ASTM A403 WPS31254 Buttweld Fittings Quote Today!